The Role of Corrosion Coupons in Corrosion Monitoring

- matintegrity

- Oct 10, 2023

- 2 min read

Updated: Oct 11, 2023

Corrosion monitoring is a critical aspect of maintaining the integrity and safety of industrial systems. In this comprehensive article, we'll delve into the essential role played by corrosion coupons in corrosion monitoring and explore their selection, advantages, limitations, placement within the system, exposure time considerations, and industry standards.

This photo depicts a corrosion coupon after the first 30-day period of exposure to the internal pipeline conditions, the weight loss coupon registered a 1.28 (MPY) wall loss rate at six o’clock position. Photo credit: https://cathodic-protection-solutions.com

The Significance of Corrosion Monitoring

Before we dive into the specifics of corrosion coupons, let's emphasize the importance of corrosion monitoring. The choice of corrosion monitoring technique is influenced by various factors, including the type of process, materials used, and available resources. While budgets can sometimes limit options, the selection of an appropriate monitoring tool can significantly impact the longevity and safety of industrial assets.

Corrosion Coupons: Simple Yet Effective

Corrosion coupons are a popular choice in corrosion monitoring due to their simplicity, cost-effectiveness, ease of installation, and low lab analysis costs. These coupons offer direct measurements of corrosion rates, providing precise data on the level of material loss due to corrosion. This direct method ensures that you don't have to rely on assumptions or estimations; you get concrete information about what's happening within your system.

Direct vs. Indirect Techniques

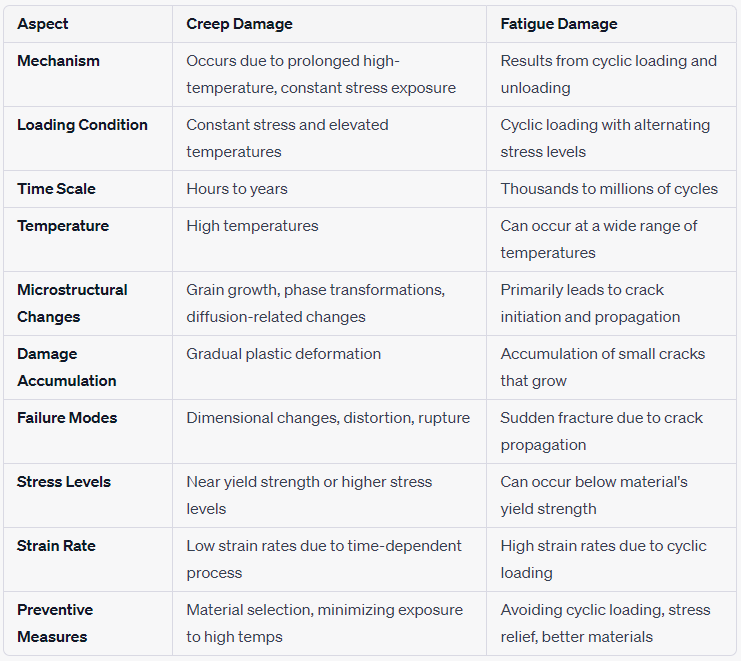

Corrosion monitoring techniques can be categorized into two main types: direct and indirect as visualized in below tables:

Direct techniques offer immediate and accurate insights into corrosion rates, leaving no room for assumptions.

Indirect techniques provide information related to corrosion parameters but may not directly measure corrosion rates.

The Versatility of Corrosion Coupons

One of the most significant advantages of corrosion coupons is their versatility. They can be used to monitor a wide range of corrosion-related issues in various environments, making them a reliable choice for corrosion engineers. Whether you're dealing with water, gas, liquids, oil, or multiphase systems, corrosion coupons can provide valuable data.

What Can You Extract from Corrosion Coupons?

Corrosion coupons yield critical information beyond corrosion rates. Here are six key pieces of data you can obtain:

This photo depicts accumulation of these sediments with the monitoring devices set at the 6 o’clock access fitting position. Obviously, regardless of coupon type and coupon holder length, it is possible to provide and analyse a real sample of sediments and governing fluid conditions, and consequently, perform a suitable corrective action.

Photo Credit: https://www.materialsperformance.com

Advantages and Limitations of Corrosion Coupons

While corrosion coupons offer numerous advantages, they also have limitations:

Choosing the Right Locations

Selecting the appropriate locations for corrosion coupons is crucial. Consider areas where water accumulation, impact, or corrosion failures are likely. Mathematical models and industry standards can help determine optimal placement. Ensure proper documentation to identify monitoring equipment accurately.

Exposure Time Considerations

The exposure time of corrosion coupons depends on the desired outcome. Short-term exposures (15-45 days) provide quick insights, while long-term exposures (60-90 days) help detect pitting and microbiologically induced corrosion. Consistency in exposure times is essential for accurate data interpretation.

Industry Standards and Guidelines

In the field of corrosion monitoring, adherence to industry standards is paramount. The following standards provide guidance on the selection, installation, and maintenance of corrosion coupons:

Give us your feedback and share your experience and insights in this topic

Comments