9 Characteristics you need to know to distinguish between Polythionic Acid SCC and Chloride SCC

- matintegrity

- Dec 31, 2022

- 3 min read

Austenitic stainless steels are particularly susceptible to polythionic acid stress corrosion cracking (PASCC) and chloride stress corrosion cracking (CLSCC). Polythionic acid stress corrosion cracking (SCC) and chloride stress corrosion cracking (SCC) are two different types of corrosion that can occur in metals. Both types of SCC are caused by a combination of tensile stress and corrosive environments, but there are some key differences between polythionic acid SCC and chloride SCC that you can use to distinguish between them.

Ask Mat Integrity team of any technical queries you have, we will do our best to help you.

Corrosive environment:

Polythionic acid SCC occurs in the presence of polythionic acids, which are a group of compounds that contain multiple thionic (sulfur-containing) groups. These acids can form in metal alloys, such as stainless steel, when they are subjected to high temperatures and stresses.

Chloride SCC, on the other hand, occurs in the presence of chlorides, which are compounds containing chlorine. Chlorides can be found in many different environments, including saltwater, industrial processes, and de-icing agents.

Susceptible materials:

Polythionic acid SCC is most commonly found in stainless steel alloys that contain high levels of sulfur, such as Type 316 stainless steel.

Chloride SCC can occur in a wide range of metals, including steel, aluminium, copper, and brass.

Crack appearance:

Polythionic acid SCC typically results in the formation of small, shallow cracks on the surface of the metal. These cracks can be difficult to see with the naked eye and may require the use of a microscope to be detected.

Chloride SCC, on the other hand, often results in the formation of deeper, more visible cracks.

Impact on mechanical properties:

Polythionic acid SCC can lead to a reduction in the strength and ductility of the affected metal, making it more prone to failure.

Chloride SCC can also have a significant impact on the mechanical properties of the affected metal, leading to a reduction in strength and an increase in brittleness.

Detection and prevention:

Polythionic acid SCC can be difficult to detect, as it often occurs in the absence of visible corrosion. To prevent polythionic acid SCC, it is important to control the temperature and stress levels to which the metal is subjected.

Chloride SCC can be detected using corrosion monitoring techniques, such as corrosion rate measurement or corrosion mapping, and can be prevented by controlling the levels of chlorides in the environment and using corrosion-resistant materials.

Occurrence:

Polythionic acid SCC is most commonly found in sensitized stainless steel alloys that have been heat treated or subjected to high levels of stress. It can also occur in other metals that contain sulfur, such as copper-base alloys and aluminium alloys.

Chloride SCC can occur in a wide range of metals and alloys, but is most commonly found in steel and aluminium alloys that have been exposed to chloride-containing environments.

Prevention and control measures:

To prevent and control polythionic acid SCC, it is important to maintain proper control of temperature and stress levels and to use corrosion-resistant materials whenever possible.

To prevent and control chloride SCC, it is important to control the levels of chlorides in the environment and to use corrosion-resistant materials or protective coatings. It is also important to properly maintain and repair any damage that has occurred.

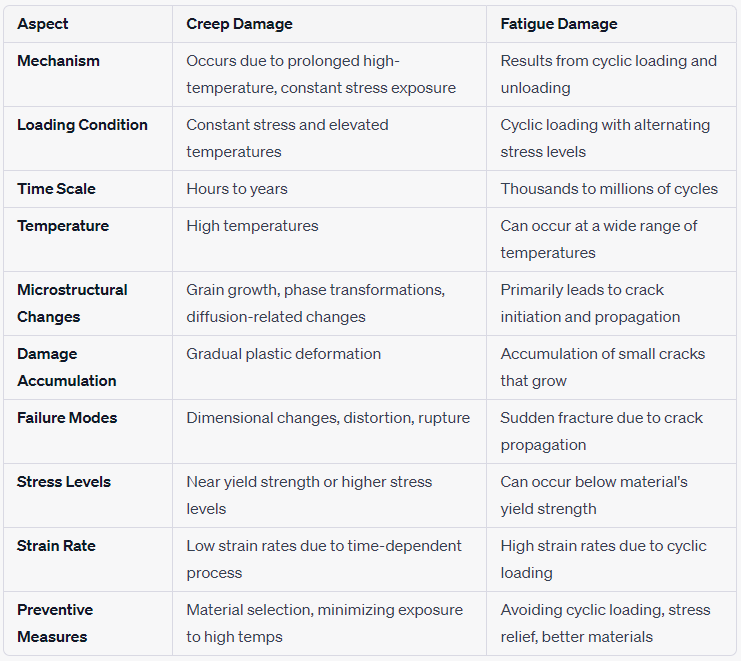

In addition the following table explains the 9 main Characteristics you need to know to distinguish between both cracking mechanisms (in accordance with API571_2020 Ed).

Cracking is usually initiates and propagates along the surface | Cracking may propagate rapidly through the wall thickness of piping and components in a matter of minutes or hours |

Cracking usually occurs at metal temperatures above about 140 °F (60 °C) | Cracking is usually quite localized and may not be evident until a leak appears |

Chloride content, temperature, pH, tensile stress, presence of oxygen, and alloy composition are critical factors | The combination of sulfide scale, air (i.e. oxygen), and moisture creates sulfur acids on the surface that then cause polythionic acid stress corrosion cracking (PTA SCC) |

Surface-breaking cracks can occur from the process side or externally under insulation | Usually occurs adjacent to welds or in high-stress areas |

The component usually shows no visible signs of corrosion | Corrosion or loss in thickness is usually negligible |

Characteristic stress corrosion cracks have many branches and may be visually detectable as spider web or craze cracking on the surface. | Characteristic stress corrosion cracks propagate intergranularly along the grain boundaries. |

Metallography of cracked samples typically shows branched, transgranular cracks. Cracking of sensitized 300 series SS may be intergranular | Metallography of cracked samples typically shows cracking propagates intergranularly, moreover cracks might be filled with a tight deposit |

High-magnification photomicrograph of metallographic sample usually shows fracture surfaces typically have a brittle appearance | High-magnification photomicrograph of metallographic sample usually shows intergranular cracking and grain dropping |

Cracking may be either process side or external. | It normally occurs during shutdowns or start-ups internally or in the process side. |

Comments