Overheating Failures In Boilers

- matintegrity

- Mar 29, 2021

- 2 min read

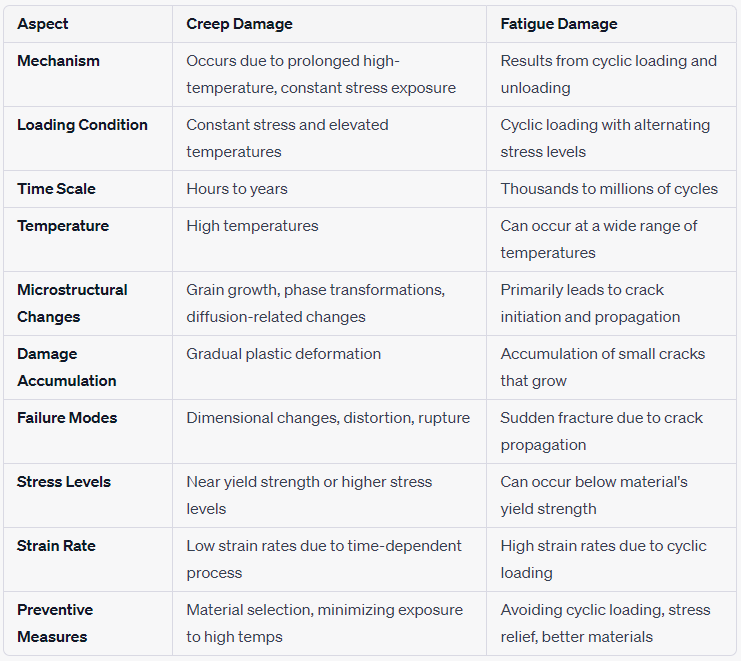

Mechanical components of a boiler can fail due to reasons such as creep, fatigue, erosion, and corrosion. Creep is defined as the time-dependent deformation of a material at elevated temperature under mechanical stresses of constant magnitude. The failure resulted from creep is referred to as a creep or stress rupture failure. Stress rupture failures also cover failure due to short-term or long-term overheating.

The waterwalls, superheater, and reheater tubes carrying water or steam in a boiler are all susceptible to overheating failure. Fracture due to overheating generally takes place along the longitudinal axis of the tube, and may be accompanied by fracture in the circumferential direction as well.

The visual appearance of the fracture is like a fish mouth. Based on the degree of plastic deformation and the resultant thinning that the tube undergoes prior to fracture, it is called a thick-lip or thin-lip fish-mouth fracture. Depending on the time to which the tube has been exposed to high temperature prior to fracture, the failure is called short term overheating (with exposure time as low as a few minutes) or long-term overheating (with exposure time of a few months to a few years).

Need advise or Have a question

Do you have a problem in selecting the right materials? Do you need more information? Whether you prefer to call through your company or as individual, please contact us or send your email and we will contact you.

Long-Term Overheating or Thick-Lip Type Fracture Thick-lip fractures generally occur after long-term or prolonged overheating at a temperature slightly above the maximum safe working temperature for the tube material. It results in very little or no reduction in the wall thickness with little or moderate bulging of the tube. The failure is accompanied by formation of a scale or corrosion product on the inner side of the tube.

Don not hesitate to share your thoughts in comments.

The most frequently encountered reasons for long-term overheating failures include partially restricted water or steam flow due to partial blocking of the tubes; buildup of an internal scales or deposits leading to an insulating effect, which thereby reduces heat transfer across the tube wall and hence overheating tube wall. In addition, the following factors may increase the susceptibility to this failure such as:

Normal heat input from the burners due to uneven burner adjustment;

Steam blanketing in horizontal or inclined tubes;

Undesired channeling of fire-side gases.

Apart from a change in the physical condition of the tube, long-term overheating also leads to microstructural changes. In the case of carbon and low-alloy steels, long-term overheating below Ac1 results in the decomposition of pearlite into ferrite and globular or spheroidal carbide, finally causing significant loss of strength. With longer exposure, it can even lead to degradation of the material by way of "void formation" along the grain boundaries of the steel followed by grain separation, and finally failure of the tube through the stress-rupture mode.

To Be continued the next post about short-term overheating

Comments