Overheating Failures In Boilers Cont..

- matintegrity

- Apr 1, 2021

- 4 min read

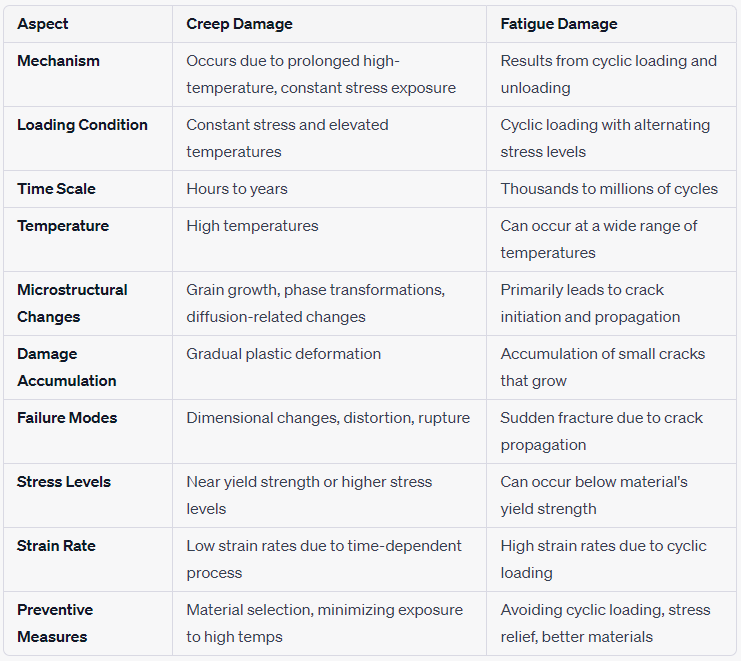

Mechanical components of a boiler can fail due to reasons such as creep, fatigue, erosion, and corrosion. Creep is defined as the time-dependent deformation of a material at elevated temperature under mechanical stresses of constant magnitude. The failure resulted from creep is referred to as a creep or stress rupture failure. Stress rupture failures also cover failure due to short-term or long-term overheating.

The waterwalls, superheater, and reheater tubes carrying water or steam in a boiler are all susceptible to overheating failure. Fracture due to overheating generally takes place along the longitudinal axis of the tube, and may be accompanied by fracture in the circumferential direction as well.

The visual appearance of the fracture is like a fish mouth. Based on the degree of plastic deformation and the resultant thinning that the tube undergoes prior to fracture, it is called a thick-lip or thin-lip fish-mouth fracture. Depending on the time to which the tube has been exposed to high temperature prior to fracture, the failure is called short term overheating (with exposure time as low as a few minutes) or long-term overheating (with exposure time of a few months to a few years).

Need advise or Have a question

Do you have a problem in selecting the right materials? Do you need more information? Whether you prefer to call through your company or as individual, please contact us or send your email and we will contact you.

Short-Term Overheating or Thin-Lip Type of Fracture

Short-term or rapid overheating of carbon and low-alloy steel tubes above the AC1 temperature typically around 723 °C, or 1333 °F, leads to a thin-lip fracture. This is a high-temperature tensile fracture of the tube material because of the decrease in its yield strength due to elevated temperature.

Don not hesitate to share your thoughts in comments.

A tube will fracture in the thin-lip mode with a fish-mouth appearance when it is subjected to rapid overheating above the safe working temperature for the tube material.

There is considerable reduction in the wall thickness of the tube and the rupture location is often like a knife-edge. A thin-lip fracture is also characterized by a considerable swelling or bulging of the tube surrounding the rupture area. Lateral bending of the tube is noticed when high-velocity steam passing through the tube tries to escape from the ruptured area.

Some frequently encountered factors accounting for thin-lip failure of boiler tubes are as follows:

Tube blockage due to scales, flyash...etc., particularly for superheaters and reheaters;

Tube leakage, mainly in the case of waterwall tubes, and the resultant starvation and overheating due to flame impingement;

low water levels in the boiler drum; rapid start-ups; and excessive load swings.

Microstructural changes in a thin-lip fracture are governed by the temperature to which the tube is heated with respect to its recrystallization temperature. Rapid heating below the recrystallization temperature produces severely elongated grains. On the other hand, rapid heating to a temperature between AC1 and AC3 (above the recrystallization temperature) produces a pearlitic or bainitic structure.

Inspection and monitoring

Short-term overheating damage or failure can occur in such a short time that inspection as a mitigative or preventive measure may not be possible. However, there are several inspection and monitoring methods applicable to dealing with short-term overheating. Some of these methods are explained below:

Visual inspection: Components that are accessible during shutdowns of boilers: can be visually inspected to find tube bulging, sagging, and other types of deformation. Damage can be quantified by strapping the tubing and taking UT thickness measurements. However, not all damages are visually apparent, and moreover it is always advisable to detect the hot spots earlier.

Infrared thermography: Monitoring of heater tubes for localized hot spots could indicate locations susceptible to short-term overheating failures. This technique can be employed while the equipment is in operation using either installed or portable IR thermography monitoring tools.

Thermocouples: can be installed to monitor temperatures of heater tubes as well as other equipment, including refractory lined equipment, during operation. Thermocouples can be attached directly to the metal surface or placed under insulation for approximate temperature measurement. However, thermocouples often cannot identify localized hot spots, logically because placement of thermocouples often does not coincide with the location of localized hot spots arising later.

Refractory inspection: refractory damages should be inspected during shutdowns as it may indicate possible short-term overheat damage or may provide clues for where to look for possible tube or other component overheat damage.

Field metallographic replication or FMR: of accessible components can reveal the microstructure and is used to evaluate creep void formation. With knowledge of operating conditions, FMR may be employed for remaining life assessments of affected components.

Boroscopic examination: Steam blanketing that results in long-term localized caustic corrosion rather than a short-term overheating failure may be detected by VT of the tube internals using a boroscope.

Other NDE methods: localized thinning inspection techniques such as straight beam UT, PAUT, or TOFD can be used, but in the case where the steam generation tubes are finned, these techniques are not applicable.

Comments